Bolt Specifications

- General Overview

- Tips and Tricks

- Related Tools

-

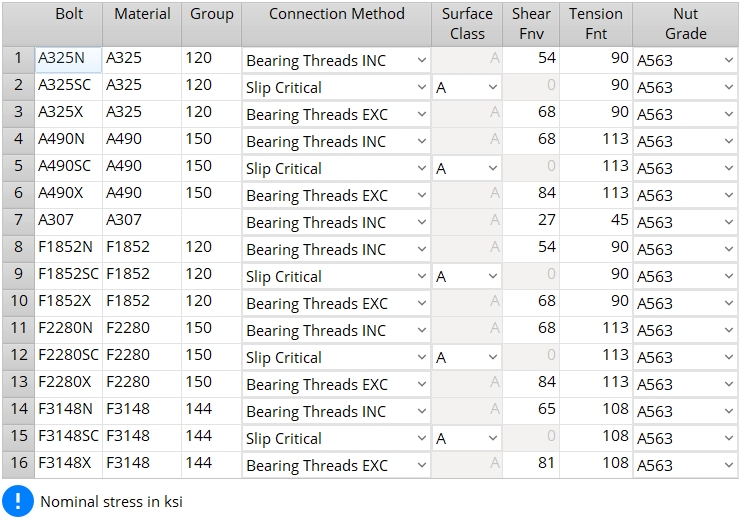

When you open the window, the settings shown will be for your selected design method. Changing design methods may result in changed bolt settings.

Bolt: Any character string to designate the name of the bolt type. A bolt defined here becomes selectable ( ![]() ) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

Allowable entries: The bolt type name entered here can be any name you like (Fred, Louise, Harvey). It is a good idea to only add bolts that are recognized within the industry as having particular properties suitable for use in steel construction.

Material: A307 or A325 or A490 or F1852 or F2280 are the material types filled out on this table in the default Job Settings file. Any other materials that may appear on this window have been added by users.

The default bolt set: Connection design recognizes A325/F1852 and A490/F2280 as materials for high strength connections. A307 material is recognized as material for "soft bolts" and used for " Erection bolts ."

Restrictions: A material other than A325/F1852 or A490/F2280 that is used for bolts in a moment end plate causes failure of the connection and produces the error message: " Design valid only for A325/F1852 or A490/F2280 bolts ." For a shear plate, you get the error message: " Design valid only for A325 or F1852 bolts " if material other than A325/F1852 is used for the bolt.

Group: 120 or 144 or 150 according to the material strength of high-strength bolts.

Connection Method: Bearing Threads INC or Bearing Threads EXC or Slip Critical .

' Bearing Threads INC ' is for a bearing-type connection with threads included in the shear plane.

' Bearing Threads EXC ' is for a bearing-type connection with threads excluded from the shear plane.

' Slip Critical ' is for bolts in slip-critical connections. For ' Slip Critical ' bolts, you also have to enter a " Surface Class ."

Surface Class: A or B . This applies when the selected " Connection Method " is ' Slip Critical '.

Class ' A ' has a Slip Coefficient of 0.30 and applies to uncoated clean mill scale steel surfaces and blast-cleaned steel surfaces with Class A coatings.

Class ' B ' has a Slip Coefficient of 0.50 and applies to uncoated blast-cleaned steel surfaces and blast-cleaned steel surfaces with Class B coatings.

Shear (Fnv): The nominal shear stress ( Fnv ) for the type of bolt being defined (in ksi or MPa).

AISC: The default values entered here are from Table J3.2.

Tension (Fnt): The nominal tensile stress ( Fnt ) for the type of bolt being defined (in ksi or MPa).

AISC: The default values entered here are from Table J3.2.

Nut Grade: Any grade that has been entered to the Nut and Washer Schedule can be selected ( ![]() ) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

When connection design applies a heavy hex nut to the primary position on a bolt, it uses the grade that is selected here as the " Primary nut grade ."

Other AISC Bolt Settings:

Bolt: Any character string to designate the name of the bolt type. A bolt defined here becomes selectable ( ![]() ) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

Allowable entries: The bolt type name entered here can be any name you like ( Fred , Louise , Harvey ). It is a good idea to only add bolts that are recognized within the industry as having particular properties suitable for use in steel construction.

Material: A307 or A325 or A490 or F1852 or F2280 are the material types filled out on this table in the default Job Settings file. Any other materials that may appear on this window have been added by users.

The default bolt set: Connection design recognizes A325/F1852 and A490/F2280 as materials for high strength connections. A307 material is recognized as material for "soft bolts" and used for " Erection bolts ."

Restrictions: A material other than A325/F1852 or A490/F2280 that is used for bolts in a moment end plate causes failure of the connection and produces the error message: " Design valid only for A325/F1852 or A490/F2280 bolts ." For a shear plate, you get the error message: " Design valid only for A325 or F1852 bolts " if material other than A325/F1852 is used for the bolt.

Connection Method: Bearing Threads INC or Bearing Threads EXC or Slip Critical . AISC 13th Edition: Values entered here are used for bearing type bolts per equation J3-1 from the AISC Steel Construction Manual. For slip-critical bolts, connection design calculates the strength limit state using equation J3-4 from the AISC Steel Construction Manual.

' Bearing Threads INC ' is for a bearing-type connection with threads included in the shear plane.

' Bearing Threads EXC ' is for a bearing-type connection with threads excluded from the shear plane.

' Slip Critical ' is for bolts in slip-critical connections. For ' Slip Critical ' bolts, you also have to enter a " Surface Class ." Connection design uses the " AISC 13th edition limit state for slip-critical bolt design " that is set in Bolt Settings when designing slip-critical bolts.

Surface Class: A or B . This applies when the selected " Connection Method " is ' Slip Critical '.

Class ' A ' has a Slip Coefficient of 0.35 and applies to uncoated clean mill scale steel surfaces and blast-cleaned steel surfaces with Class A coatings.

Class ' B ' has a Slip Coefficient of 0.50 and applies to uncoated blast-cleaned steel surfaces and blast-cleaned steel surfaces with Class B coatings.

Hole Factors, hsc (apply to ' Slip Critical ' bolts only)

Standard: The hole factor ( hsc ) for calculating the nominal slip resistance ( Rn ) for the bolt being defined when it is used in a standard round hole in a slip-critical connection.

Oversized: Same as " Standard ," except that this applies to oversized holes.

Short Slot: Same as " Standard ," except that this applies to short slots.

Long Slot: Same as " Standard ," except that this applies to long slots.

Shear (Fnv): The nominal shear stress ( Fnv ) for the type of bolt being defined (in ksi or MPa).

Tension (Fnt): The nominal tensile stress ( Fnt ) for the type of bolt being defined (in ksi or MPa).

Nut Grade: Any grade that has been entered to the Nut and Washer Schedule can be selected ( ![]() ) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

Standard ASD: The maximum allowable shear stress in ksi for ' Imperial ' (or MPa for ' Metric ') that the type of bolt being defined can withstand when used in a standard hole. A standard hole is a round hole that is typically 1/16 inch larger than the bolt diameter.

Oversized ASD: The maximum allowable shear stress in ksi (MPa for ' Metric ') for the type of bolt being defined when used in an oversized hole. An oversized hole is a round hole that is typically 1/8 inch larger than the bolt diameter.

Short Slot ASD: The maximum allowable shear stress in ksi (MPa for ' Metric ') for the type of bolt being defined when it is used in a short slot.

Long Slot ASD: The maximum allowable shear stress in ksi (MPa for ' Metric ') for the type of bolt being defined when it is used in a long slot.

Tension ASD: The maximum allowable tension in ksi (MPa for ' Metric ') for the type of bolt being entered.

Standard LRFD: The maximum allowable shear stress in ksi for ' Imperial ' (orMPa for ' Metric ') that the type of bolt being defined can withstand when used in a standard hole. A standard hole is a round hole that is typically 1/16 inch larger than the bolt diameter.

Oversized LRFD: The maximum allowable shear stress in ksi (MPa for ' Metric ') for the type of bolt being defined when used in an oversized hole. An oversized hole is a round hole that is typically 1/8 inch larger than the bolt diameter.

Short Slot LRFD: The maximum allowable shear stress in ksi (MPa for ' Metric ') for the type of bolt being defined when it is used in a short slot.

Long Slot LRFD: The maximum allowable shear stress in ksi (MPa for ' Metric ') for the type of bolt being defined when it is used in a long slot.

Tension LRFD: The nominal tensile strength in ksi (MPa for ' Metric ') for the type of bolt being entered.

Australian Bolt Settings

Bolt: Any character string to designate the name of the bolt type. A bolt defined here becomes selectable ( ![]() ) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

46/S and 8.8/S and 8.8/TB and 8.8/TF are bolt types that are filled out on this table in the default Job Settings file. Refer to Table 9.3.1 of the AS 4100 - 1998 . Any other bolts that may appear on this window have been added by users.

Restrictions: If you use a bolt other than 8.8/TB or 8.8/TF for a moment end plate, connection design fails the connection and gives you the error message: " Design valid only for 8.8/TB or 8.8/TF bolts ."

Bolt standard: AS/NZS 111 or AS/NZS 1252 are standards that are filled out on this table in the default Job Settings file. You can add other standards if you choose. Refer to Table 9.3.1 of the AS 4100 - 1998 .

Grade: 4.6 or 8.8 are the choices that are filled out on this table in the default Job Settings file. Refer to Table 9.3.1 of the AS 4100 - 1998 .

Method of Tightening: Snug Tight or Full Tensioning . Refer to Table 9.3.1 of the AS 4100 - 1998 .

Connection Method: Bearing-type or Slip Critical (friction type connections in which slip in the serviceability limit state is required to be limited). Refer to Table 9.3.1 of the AS 4100 - 1998 .

Slip Factor: The slip factor as specified in Clause 9.3.3.2 of the AS 4100 - 1998 .

Standard: The hole type factor ( kh ) for calculating the shear capacity ( Vsf ) for the bolt being defined when it is used in a standard hole in a slip-critical connection. See Clause 9.3.3.1 of the AS 4100 - 1998 .

Oversized: Same as " Standard ," except that this applies to oversized holes.

Short Slot: Same as " Standard ," except that this applies to short slots.

Long Slot: Same as " Standard ," except that this applies to long slots.

Tension: The minimum tensile strength ( fuf ) in ksi or MPa (depending on the primary dimension " Units "). Refer to Table 9.3.1 of the AS 4100 - 1998 .

Nut Grade: Any grade that has been entered to the Nut and Washer Schedule can be selected ( ![]() ) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

Canadian Bolt Settings

Bolt: Any character string to designate the name of the bolt type. A bolt defined here becomes selectable ( ![]() ) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

Material: A307 or A325 or A490 or F1852 or F2280 are the material types filled out on this table in the default Job Settings file (see below for allowable entries). Any other materials that may appear on this window have been added by users.

The default bolt set: Connection design recognizes A325/F1852 and A490/F2280 as materials for high strength connections. A307 material is recognized as material for "soft bolts" and used for " Erection bolts ."

Restrictions: A material other than A325/F1852 or A490/F2280 that is used for bolts in a moment end plate causes failure of the connection and produces the error message: " Design valid only for A325/F1852 or A490/F2280 bolts ." For a shear plate, you get the error message: " Design valid only for A325 or F1852 bolts " if material other than A325/F1852 is used for the bolt.

Connection Method: Bearing Threads INC or Bearing Threads EXC or Slip Critical .

' Bearing Threads INC ' is for a bearing-type connection with threads included in the shear plane.

' Bearing Threads EXC ' is for a bearing-type connection with threads excluded from the shear plane.

' Slip Critical ' is for bolts in slip-critical connections. For ' Slip Critical ' bolts, you also have to enter a " Surface Class ."

Surface Class: A or B or C . This applies when the selected " Connection Method " is ' Slip Critical '.

Class ' A ' applies to clean mill scale and blast-cleaned surfaces with Class A coatings.

Class ' B ' applies to blast-cleaned surfaces and blast-cleaned surfaces with Class B coatings.

Class ' C ' applies to hot dip galvanized with wire brushed surfaces.

Ks: The mean slip coefficient ( Ks ) used to determine the slip resistance of a bolted joint subjected to shear in a slip-critical connection. Refer to Clause 13.12.2.2 and Table 3 of the CISC.

C1: The coefficient ( C1 ) used to determine the slip resistance of a bolted joint subjected to shear in a slip-critical connection. Refer to Clause 13.12.2.2 and Table 3 of the CISC.

Thread Factor: The factor to be applied to the calculation of Vr in Clause 13.12.1 of the CISC. When the " Connection method " is ' Bearing Threads EXC ', the default factor is ' 1 '. When the " Connection method " is ' Bearing Threads INC ', the default factor is ' 0.70 '.

Tension: The specified minimum tensile strength ( Fu ) in ksi (MPa for ' Metric ') for bolts whose diameters are less than or equal to the " Limiting Bolt Dia (in inches) ". See Clause 13.12.1.1 of the CISC.

Limiting Bolt Dia (in inches): The bolt diameter (in inches) that divides where connection design applies the " Tension " or the " Reduced Tension " to the bolt. See Clause 13.12.1.1 of the CISC.

Reduced Tension: The specified minimum tensile strength ( Fu ) in ksi (MPa for ' Metric ') for bolts that are larger in diameter than the " Limiting Bolt Dia (in inches) ". See Clause 13.12.1.1 of the CISC.

Nut Grade: Any grade that has been entered to the Nut and Washer Schedule can be selected ( ![]() ) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

Eurocode Bolt Settings

Bolt: Any character string to designate the name of the bolt type. A bolt defined here becomes selectable ( ![]() ) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

) on list boxes for bolt type throughout your current Job (for example, as the " NM bolt type to supported ").

4.6A and 4.8A and 5.6A and 5.8A and 6.8A and 8.8A and 8.8C and 10.9A and 10.9C are bolt types that are filled out on this table in the default Job Options setup file.

Material: 4.6 or 4.8 or 5.6 or 5.8 or 6.8 or 8.8 or 10.9 are the material types filled out on this table in the default Job Settings file. Any other materials that may appear on this window have been added by users.

Restrictions: A material other than 8.8 that is used for bolts in a moment end plate or shear plate causes failure of the connection and produces the end connection failure message " Design valid only for class 8.8 bolts ."

Connection Method: Bearing Threads INC or Bearing Threads EXC or Slip Critical .

' Bearing Threads INC ' is for a bearing-type connection with threads included in the shear plane. That is to say, the shear plane passes through the unthreaded portion of the bolt.

' Bearing Threads EXC ' is for a bearing-type connection with threads excluded from the shear plane. That is to say, the shear plane passes through the threaded portion of the bolt.

' Slip Critical ' is for bolts in slip-critical connections.

Surface Class: A or B or C or D . See Table 18 of BS EN 1090-2:2008+A1:2011. You need to enter a " Surface Class " when ' Slip Critical ' is selected as the bolt's " Connection Method ."

Class ' A ' has a slip factor of 0.50 and is for not-pitted surfaces that have been blasted with shot or grit with loose rust removed.

Class ' B ' has a slip factor of 0.40 and is for surfaces that have been blasted with shot or grit and spray-metallized with an aluminum- or zinc-based product.

Class ' C ' has a slip factor of 0.30 and is for surfaces that have been blasted with shot or grit with alkali-zinc silicate paint with a thickness of 50 µm to 80 µm.

Class ' D ' has a slip factor of 0.20 for as-rolled surfaces.

Bearing Coefficient: You need to enter a " Bearing Coefficient " when ' Bearing Threads INC ' or ' Bearing Threads EXC ' is selected as the bolt's " Connection Method ." The default choices made here are based on the values specified for a v in the "Shear resistance per shear plane" failure mode in Table 3.4 of BS EN 1993-1-8:2005.

| Eurocode specifications for the value of a v | |

| Connection Method | Bolt Material |

| Bearing Threads Included |

For 4.6, 5.6 and 8.8, a v = 0.6

For 4.8, 5.8, 6.8 and 10.9, a v = 0.5 |

| Bearing Threads Excluded | a v = 0.6 |

Yield strength (fyb) : The nominal yield strength of the bolt. If you are using imperial dimensioning, nominal stress is measured in kips/sq. inch (ksi). If you are using metric dimensioning, yield strength is measured in megapascals (MPa).

Ultimate Strength (fub) : The nominal ultimate strength of the bolt. If you are using imperial dimensioning, nominal stress is measured in kips/sq. inch (ksi). If you are using metric dimensioning, yield strength is measured in megapascals (MPa).

Nut Grade: Any grade that has been entered to the Nut and Washer Schedule can be selected ( ![]() ) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

) here, on this list box . Line 1 on the Washer and Nut Schedule sets the default grade that is selected when you create a new bolt definition.

|

|

OK (or the Enter key) closes this screen and applies the settings.

Cancel (or the Esc key) closes this screen without saving any changes.

Reset undoes all changes made to this screen since you first opened it. The screen remains open.

- Washer Settings (to assign washers to bolt type entered here)

- Connection design method (sets which tab on this window applies)

- Bolt Settings (to assign type to default situations)

- Hole Edit window (to assign type to individual bolts)

- Bolt Type (to assign type to individual beam connections)

or

or